When discussing cruise ship fuel economy, the scale is monumental. Standard metrics like miles per gallon are insufficient; in the maritime industry, efficiency is measured in tons of fuel per hour. A large cruise ship can consume approximately 250 tons of fuel daily, a figure that highlights the immense energy required to operate these floating cities.

The Reality of Fueling a Floating City

A modern cruise ship is essentially a mobile metropolis, complete with hotels, theaters, restaurants, and thousands of inhabitants, all needing to be propelled across vast oceans. This operational reality presents a unique energy challenge, making fuel consumption a central issue in maritime logistics.

Historically, this demand has been met by heavy fuel oil (HFO), a dense, viscous, and cost-effective byproduct of the oil refining process. While economical, HFO carries significant environmental and operational complexities, placing fuel management at the forefront of the cruise industry's strategic planning.

A Matter of Immense Scale

To grasp the concept of cruise ship fuel economy, a comparison with more familiar vehicles is necessary. The sheer numbers can otherwise be difficult to contextualize.

A large cruise vessel may burn through 250 tons of fuel per day, which translates to about 10 tons for every hour of sailing. The fuel tanks are correspondingly massive, with some holding up to 1.33 million gallons—a volume equivalent to five million large soda bottles. For perspective, a typical passenger car holds 12 to 20 gallons, while a large commercial aircraft might hold around 60,000. Further data on this topic is available from how much fuel a cruise ship holds on CruiseMummy.co.uk.

The following table provides a clear comparison of fuel consumption across different vehicle types, illustrating the unique scale of maritime operations.

Fuel Consumption at a Glance

| Vehicle Type | Typical Fuel Capacity (Gallons) | Typical Daily Consumption (Tons) | Analogy |

|---|---|---|---|

| Large Cruise Ship | 1,330,000 | ~250 | A mobile city needing constant power |

| Boeing 747 | 60,000 | Varies by flight | Enough for a long-haul flight across continents |

| Semi-Truck | 150 | Varies by route | Cross-country hauls over several days |

| Family Car | 15 | Varies by use | A week's worth of commuting and errands |

This immense fuel demand dictates the logistical framework of the entire cruise industry.

"For the cruise sector, more frequent bunkering operations actually afford considerable opportunity for fuel flexibility. This emphasis on flexibility is a high priority as we move forward."

– Bob Alton, Senior Director of Technical Programs and Decarbonization at Princess Cruises

As Alton's statement indicates, the logistics of refueling are as critical as consumption itself. The constant need for massive fuel volumes influences everything from port operations and route planning to the industry's economic model.

The Stakes of Consumption

This high rate of fuel consumption has two primary consequences that drive the conversation around cruise ship fuel economy.

- Economic Impact: Fuel represents one of the largest single operating expenses for any cruise line. Fluctuations in global oil prices can significantly affect profitability, with ramifications for ticket prices and shareholder returns.

- Environmental Responsibility: The combustion of traditional marine fuels like HFO releases pollutants such as sulfur oxides (SOx), nitrogen oxides (NOx), and carbon dioxide (CO2). This has subjected the industry to intense scrutiny from regulators and the public, prompting a shift toward cleaner fuels and more efficient operations.

Ultimately, the topic of cruise ship fuel economy is not merely an academic exercise. It is a core business challenge that influences ship design, shapes global environmental policy, and dictates the financial stability of a multi-billion-dollar industry. Understanding this scale is the first step in appreciating the complex solutions being developed for a more sustainable future.

How We Measure Fuel Efficiency at Sea

Determining the "miles per gallon" for a floating city is more complex than a simple calculation. A ship's fuel efficiency is a function not only of the distance it travels but of the total work it performs.

This includes transporting thousands of passengers and crew, carrying cargo, and sustaining extensive hotel operations 24/7—all while navigating unpredictable maritime conditions. To achieve accurate and comparable assessments, the maritime sector uses specific, internationally recognized metrics. These are crucial for both operational improvement and regulatory compliance.

Going Beyond Gallons Per Mile

A simple division of fuel burned by miles sailed would not provide a complete picture. Consider two identical sister ships on the same route: one carrying 4,000 passengers and the other only 2,000. The fuller ship performs significantly more "transport work," so its efficiency is fundamentally different, even if its fuel consumption is slightly higher.

For this reason, the industry employs specialized metrics that offer a more accurate representation of a ship's real-world performance.

“The challenge of methanol being a lower energy dense fuel compared to standard fuels only increases our focus on energy efficiency.”

– Bob Alton, Senior Director of Technical Programs and Decarbonization at Princess Cruises

As industry experts like Bob Alton note, the transition to new fuels such as methanol makes precise efficiency tracking more critical than ever. Different fuels have varying energy densities, so standardized indicators are essential for fair comparisons and for measuring genuine progress.

The EEOI: The Operational Scorecard

The Energy Efficiency Operational Indicator (EEOI) is a primary tool for monitoring a ship's fuel efficiency during active service. It is analogous to tracking a car's fuel economy over a year, accounting for various driving conditions and passenger loads.

Specifically, the EEOI measures the grams of carbon dioxide (CO2) emitted per unit of transport work. For cruise ships, this work is typically calculated in person-nautical miles—the number of passengers multiplied by the distance sailed. The objective is straightforward: a lower EEOI score indicates better efficiency.

This metric is vital because it allows cruise lines to see how operational decisions—such as speed adjustments, itinerary planning, and passenger load factors—directly affect their carbon footprint over time.

The EEXI: The Design Blueprint

While the EEOI assesses a ship's operational performance, the Energy Efficiency Design Index (EEXI) evaluates its technical design. It establishes a minimum energy efficiency standard for existing ships, compelling them to adopt modern technologies.

The EEXI can be thought of as a mandatory fuel economy rating applied retroactively. To meet this standard, a ship may require significant technical upgrades, including:

- Engine Power Limitation (EPL): A system that imposes a physical limit on the engine's maximum power output.

- Propulsion Optimization: Installation of more efficient propellers or propeller hub attachments.

- Hull Coatings: Application of advanced, low-friction paints that reduce hydrodynamic drag.

At its core, managing fuel efficiency depends on the ability to accurately measure and calculate energy use. To understand how this is done in other sectors, tools like industrial energy consumption calculators offer relevant insights. The fundamental principles of energy quantification underpin complex maritime metrics like EEXI and EEOI.

These indicators, mandated by the International Maritime Organization (IMO), establish a common framework for the industry. They ensure the global fleet is held to a consistent standard, enabling meaningful dialogue among regulators, operators, and the public about the industry's path toward sustainability.

Key Factors That Influence Fuel Consumption

A cruise ship's substantial fuel consumption is determined by a complex interplay of design features, operational decisions, and the energy demands of its onboard hotel facilities. These elements combine to give each voyage a unique energy footprint.

Understanding these variables is crucial for identifying how even minor adjustments can yield significant fuel savings. From the hull's shape to the captain's chosen speed, three core areas have the most substantial impact on fuel burn.

The Role of Ship Design and Hydrodynamics

A ship's fuel efficiency is largely determined long before it enters the water, during its design phase. The primary objective is to create a vessel that moves through the ocean with minimal resistance, a principle known in naval architecture as hydrodynamics.

A prominent feature affecting this is the bulbous bow, the protruding bulb at the front of the hull below the waterline. This design creates its own wave that interferes with and partially cancels the ship's natural bow wave. This hydrodynamic trick can reduce drag and improve fuel efficiency by as much as 15%.

Beyond the bow, the entire hull form is sculpted to minimize friction. A sleeker, more streamlined design reduces the power required from the engines to propel the vessel. This fundamental design principle is the first and most enduring factor in managing fuel consumption over a ship's operational life.

Operational Decisions The Captain Can Make

Once at sea, daily decisions made by the captain and crew have a direct and immediate impact on fuel use. The most significant factor is the ship's speed. The energy required to push a vessel through water increases exponentially with speed, which is why "slow steaming" has become a vital fuel conservation strategy.

Reducing speed by just a few knots can have a profound effect. For example, a 20% reduction in a ship's speed can cut daily fuel consumption by nearly 50%. This is a powerful tool for cruise lines aiming to control costs and environmental impact, though it must be balanced with itinerary schedules.

Other critical operational decisions include:

- Route Optimization: Using sophisticated weather forecasting and ocean current data to chart the most efficient course, avoiding adverse conditions that increase engine load.

- Trim Optimization: Adjusting the distribution of cargo, ballast water, and supplies to position the ship at an optimal angle in the water, thereby minimizing drag.

- Regular Hull Cleaning: Removing marine growth such as barnacles and algae to maintain a smooth hull surface. A fouled hull can increase drag and fuel consumption by over 10%.

“The challenge of methanol being a lower energy dense fuel compared to standard fuels only increases our focus on energy efficiency.”

– Bob Alton, Senior Director Technical Programs and Decarbonization, Princess Cruises

This insight from an industry veteran underscores a key point. As the sector transitions to new fuels with lower energy content, maximizing efficiency through smart operations becomes paramount.

The Surprising Impact of Hotel Operations

A modern cruise ship is more than a vessel; it is a floating resort. The energy required for "hotel operations" is immense, often accounting for 40-50% of the ship's total energy demand at sea.

This "hotel load" represents the constant power draw needed to sustain a small city. It includes everything from galley kitchens preparing tens of thousands of meals daily to powerful air conditioning systems maintaining comfort across thousands of cabins and public areas.

Consider the significant power consumption from:

- Climate Control: Heating, ventilation, and air conditioning (HVAC) systems are the largest energy consumers among hotel operations.

- Lighting: Illuminating thousands of cabins, extensive public spaces, theaters, and open decks.

- Galleys and Refrigeration: Powering industrial-scale ovens, walk-in freezers, and numerous refrigerators.

- Entertainment: Operating sound systems, stage lighting, large video walls, and attractions like water slides or ice-skating rinks.

Given the scale of this load, cruise lines are investing heavily in energy-saving hotel technologies. The adoption of LED lighting and intelligent HVAC controls is no longer optional but essential for reducing this constant power draw and improving the ship's overall fuel economy.

The Billion-Dollar Economics of Marine Fuel

For major cruise lines, fuel is not merely an expense; it is a colossal expenditure that can dictate the financial trajectory of the entire organization. The economics of marine fuel are measured in billions, creating relentless pressure to improve cruise ship fuel economy. This pursuit is driven not only by environmental responsibility but by the economic imperative to survive in a market where profit margins are vulnerable to volatile global oil prices.

This intense financial reality is the primary driver for industry investment in efficiency. When fuel constitutes such a large portion of the operational budget, even marginal improvements can result in millions of dollars in savings, enhancing profitability and influencing passenger fares.

Fuel as a Core Business Strategy

Viewing fuel consumption through a financial lens transforms it from a simple operational cost into a core strategic pillar. Every ton of fuel saved contributes directly to the bottom line, making efficiency a powerful lever for financial performance. This is why cruise lines scrutinize every operational detail, from engine tuning to itinerary planning.

The scale of this expenditure is substantial. For large cruise corporations, annual fuel costs regularly exceed billions of dollars. Carnival Corporation, for instance, reported a fuel expense of $1.88 billion in one fiscal year after consuming 2.9 million metric tons of fuel. With an average price of $617 per metric ton—before factoring in regulatory costs—the impact of volatile oil prices on the company's balance sheet is clear. These figures can be examined in their latest earnings report on CarnivalCorp.com.

This level of spending puts the drive for small gains into perspective.

A mere 1% improvement in fuel efficiency across a large fleet can translate into tens of millions of dollars in annual savings. This reality turns fuel economy into a high-stakes corporate objective.

The Ripple Effect of Oil Price Volatility

The global oil market is notoriously unpredictable. Geopolitical events, shifts in supply and demand, and global economic conditions can cause prices to fluctuate dramatically. For cruise lines, this volatility represents a significant and largely uncontrollable business risk.

When fuel prices surge, cruise companies face a difficult decision: absorb the additional cost, thereby eroding profits, or pass it on to customers through higher fares or fuel surcharges. Neither option is ideal, as both carry the risk of alienating customers and alarming investors.

- Impact on Profitability: Unexpected fuel price hikes can erase quarterly profits and lead to disappointing financial results for shareholders.

- Influence on Ticket Prices: To protect margins, cruise lines may introduce fuel supplements, directly increasing the cost of a vacation for passengers.

- Pressure on Operations: High costs intensify the need for efficiency, compelling crews to adopt practices like slow steaming and route optimization more rigorously.

The financial consequences of fuel are enormous, making proven strategies for fleet fuel management an absolute necessity for navigating a volatile market.

Economic Pressure as a Catalyst for Innovation

While government regulations are a factor, this relentless economic pressure is arguably the most potent force driving the industry toward a more sustainable future. The multi-billion-dollar cost of conventional fuel creates a compelling business case for investing in new technologies and alternative fuels that promise long-term savings.

This financial incentive accelerates the adoption of efficiency-focused solutions. It justifies the substantial upfront capital for building LNG-powered ships, retrofitting older vessels with advanced systems, and exploring next-generation fuels like methanol. In this context, sustainability and profitability are not conflicting goals but are intertwined, both driving the evolution of cruise ship fuel economy.

Innovations Driving a Greener Fleet

Confronted with high fuel costs and increasing environmental scrutiny, the cruise industry is undertaking a large-scale technological push to enhance fuel economy. This involves serious engineering aimed at delivering measurable efficiency gains. From generating a layer of air beneath the hull to employing AI for optimized navigation, these innovations are fundamentally altering the operation of modern cruise ships.

This wave of technology is a direct response to financial and regulatory pressures. Each new system contributes to building a more efficient and sustainable fleet by rethinking how these massive vessels consume power and move through water.

Riding on a Cushion of Air

One of the most significant advancements is the air lubrication system (ALS). This technology enables a ship to glide over a thin layer of microscopic bubbles rather than directly through the water, dramatically reducing frictional drag.

The system functions by pumping a controlled stream of microbubbles from units installed on the ship's flat bottom. This "carpet" of air minimizes contact between the hull and seawater. Less drag means the engines require less power to maintain speed, resulting in a direct improvement in cruise ship fuel economy.

Major cruise lines have reported that air lubrication can reduce fuel consumption and carbon emissions by 5% to 10%—a substantial saving for a vessel operating nearly year-round.

Advanced Coatings and Hull Smoothness

Another front in the battle for efficiency is the hull surface itself. A smoother hull experiences less resistance as it moves through water. However, maintaining smoothness is a constant struggle against the accumulation of marine life like barnacles and algae, a phenomenon known as biofouling.

To combat this, manufacturers have developed sophisticated anti-fouling paints. These are not ordinary coatings but high-tech surfaces designed to either slowly release biocides that prevent organisms from attaching or to create an ultra-slick surface that marine growth cannot adhere to. A clean, smooth hull can be over 10% more fuel-efficient than one with significant marine growth.

“The challenge of methanol being a lower energy dense fuel compared to standard fuels only increases our focus on energy efficiency.”

– Bob Alton, Senior Director Technical Programs and Decarbonization, Princess Cruises

As industry leaders like Bob Alton emphasize, the transition to alternative fuels makes these efficiency gains even more vital. Every unit of energy saved becomes more valuable when the fuel itself is less energy-dense.

Smarter Systems Onboard

Significant gains are also being achieved internally through smart systems that capture waste energy and reduce power consumption across thousands of components.

- Waste Heat Recovery Systems (WHRS): A ship's engines produce a tremendous amount of heat, which was traditionally lost as exhaust. A WHRS captures this thermal energy and converts it into electricity. This power can then be used for hotel loads like lighting and air conditioning, reducing the demand on the main generators.

- AI-Powered Route Optimization: Modern software utilizes artificial intelligence to process vast amounts of real-time data, including weather forecasts, ocean currents, and port schedules. It then calculates the most fuel-efficient route and speed, making continuous micro-adjustments that accumulate into significant savings over a voyage.

- Energy-Efficient Components: Every component, from HVAC systems to galley equipment, is being re-evaluated for energy performance. Among the various technological advancements contributing to a greener fleet, efficient control mechanisms are paramount. Explore how components like energy-efficient latching solenoid valves play a role in optimizing power usage across these complex systems.

Collectively, these innovations represent a clear and dedicated effort to address the fuel economy challenge. They are practical, data-driven solutions demonstrating how engineering ingenuity is shaping a more efficient future for the cruise industry.

The Shift to Alternative Fuels and Regulations

The future of cruise ship fuel is being redefined by two powerful drivers: stringent international regulations and the industry's search for cleaner, more sustainable energy sources. These forces are interconnected, creating a new operational landscape where improving cruise ship fuel economy is no longer just about cost savings but is a prerequisite for compliance and competitiveness.

The era of unrestricted heavy fuel oil use is drawing to a close. Global authorities are enforcing strict mandates with significant financial penalties, compelling a fundamental shift in how the maritime sector powers its vessels.

The Power of Regulation

Two key regulations have catalyzed this transformation. First, the International Maritime Organization's IMO 2020 sulphur cap was a landmark rule, reducing the maximum permissible sulfur content in marine fuel from 3.5% to just 0.5%. This regulation rendered traditional heavy fuel oil non-compliant unless ships were equipped with expensive exhaust gas cleaning systems, known as scrubbers.

More recently, the European Union's FuelEU Maritime initiative has intensified the pressure. This regulation focuses on reducing the greenhouse gas intensity of the energy used by ships, with progressively tighter limits over time. It creates a strong financial incentive to transition away from fossil fuels, as non-compliance results in substantial fines.

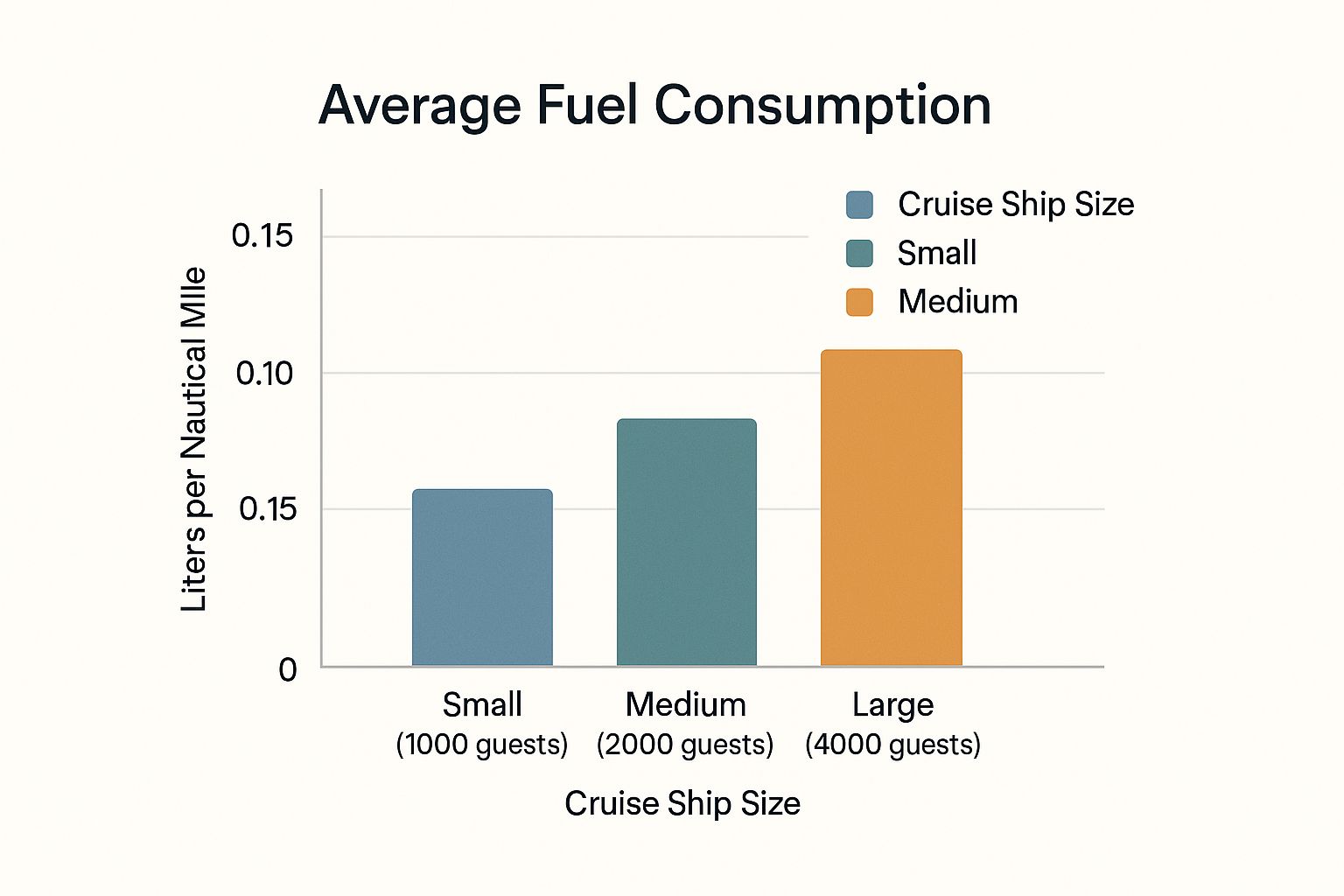

The image below illustrates the correlation between ship size and fuel consumption, a key consideration for regulators.

As shown, the largest ships have the highest fuel consumption per nautical mile, highlighting the immense challenge of decarbonizing the largest vessels in the global fleet.

Exploring the Next Generation of Fuels

With regulatory constraints tightening, the cruise industry is seriously investigating a new generation of fuels. However, no single solution has emerged. Each alternative presents a unique set of advantages and disadvantages related to production, storage, and port infrastructure availability.

The leading candidates currently under exploration are outlined below.

A closer look at these future fuels reveals the complex trade-offs the industry faces.

Future Fuel Options for Cruise Ships

| Fuel Type | Primary Advantage | Primary Challenge | Current Adoption Status |

|---|---|---|---|

| Liquefied Natural Gas (LNG) | Significantly cleaner than HFO, reducing SOx and particulate matter. | "Methane slip" (unburned methane emissions) is a major greenhouse gas concern. | The most mature alternative fuel, with a growing number of new ships being built LNG-ready. |

| Methanol | Easier to handle and store than LNG. "Green" methanol offers a path to low-carbon operations. | Lower energy density means larger fuel tanks are needed, putting more pressure on efficiency. | Gaining significant traction, with major cruise lines placing orders for methanol-capable ships. |

| Green Hydrogen & Ammonia | Potential for true zero-emission shipping in the long term. | Huge hurdles in safe onboard storage, high production costs, and a near-total lack of global infrastructure. | Very early stages; considered a long-term solution still in the research and development phase. |

This range of options indicates that while there is no single clear winner yet, the momentum toward cleaner operations is undeniable.

"The challenge of methanol being a lower energy dense fuel compared to standard fuels only increases our focus on energy efficiency."

– Bob Alton, Senior Director Technical Programs and Decarbonization, Princess Cruises

This is a critical point. As ships transition to fuels with lower energy density, every efficiency gain—from hull coatings to route optimization—becomes essential. Regulations like FuelEU Maritime are designed to make these cleaner but less energy-dense fuels the financially prudent choice.

For example, a recent report on cruise ship decarbonization from Transport & Environment analyzed the economic implications. To avoid penalties in 2050, a vessel like the Voyager of the Seas would need to operate on a fuel mix containing 83% e-methanol. While this would increase fuel costs to approximately €456 per passenger, it is significantly more economical than the €787 per passenger cost of using fossil fuels and paying the associated fines. This clear financial logic is what is truly steering the industry toward a sustainable future.

Frequently Asked Questions About Cruise Ship Fuel

As one delves into the complexities of maritime energy, several practical questions arise. This section addresses some of the most common inquiries to provide a clearer understanding of how cruise ships are powered and what the future holds.

Are Newer Cruise Ships More Fuel-Efficient?

Yes, and the difference is substantial. Each new generation of cruise ship incorporates significant technological advancements beyond cosmetic changes. These include more hydrodynamic hull designs, advanced engines, and systems for recovering and reusing waste heat.

The latest vessels powered by Liquefied Natural Gas (LNG) serve as a prime example. They are approximately 20% more fuel-efficient than their predecessors. Furthermore, they produce nearly zero sulfur emissions and significantly fewer nitrogen oxides and particulates, representing a major advancement for the industry's environmental performance and overall cruise ship fuel economy.

Why Can't Cruise Ships Use Solar or Wind Power?

In theory, this is an appealing concept, but the energy demands of a modern cruise ship are immense. The power required to propel a vessel the size of a city and operate its extensive hotel facilities far exceeds the output of current solar and wind technologies on their own. The available surface area for solar panels would generate only a small fraction of the necessary electricity.

However, the industry is not disregarding these technologies. They are being explored as supplementary power sources. Some ships utilize solar panels for specific applications, such as lighting. Companies are also investigating wind-assist systems like Flettner rotors—large, spinning cylinders that use wind to generate thrust—to reduce the load on the main engines and decrease fuel consumption.

“For the cruise sector, more frequent bunkering operations actually afford considerable opportunity for fuel flexibility. This emphasis on flexibility is a high priority as we move forward.”

– Bob Alton, Senior Director Technical Programs and Decarbonization, Princess Cruises

As industry leaders like Bob Alton suggest, flexibility is key. While solar and wind cannot yet serve as primary power sources, they are valuable components in a broader strategy to reduce dependence on traditional fuels.

How Does a Cruise Ship Refuel?

Cruise ships refuel in port through a carefully coordinated process known as bunkering. The most common method involves a specialized bunker barge, which functions as a floating fueling station, mooring alongside the cruise ship to pump fuel aboard.

In some instances, a ship may refuel directly from a land-based terminal via pipelines. In either case, it is a major logistical operation that can take several hours to complete and is governed by strict safety and environmental protocols to prevent spills.

Do Cruise Ships Dump Fuel in the Ocean?

No. The deliberate discharge of fuel into the ocean is strictly prohibited under international maritime law, most notably the MARPOL convention. In addition to the legal and environmental repercussions, fuel is an extremely expensive commodity. It would be economically irrational for a cruise line to discard it.

Violations carry severe penalties. While accidental spills or illegal discharges can occur, regulatory bodies worldwide are vigilant in monitoring and enforcing these rules to protect marine ecosystems.

Stay informed on the latest maritime industry developments with SeaWanderer. From technological breakthroughs to regulatory shifts, we provide the in-depth news and analysis professionals need. Explore more at https://seawanderer.org.

Article created using Outrank